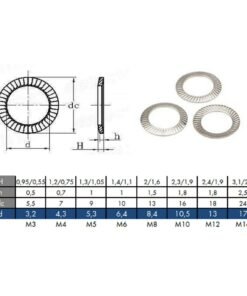

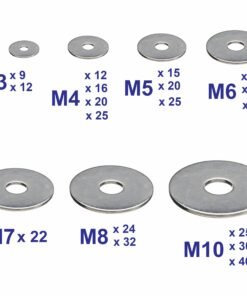

Serrated Safety Locking Washers Type S Sizes from M3 to M16 Stainless Steel

£3.95 – £7.50Price range: £3.95 through £7.50

Serrated Safety Locking Washers Type S M3 – M16 Stainless Steel

Serrated safety locking washers are an essential component, When it comes to securing fasteners. These washers are designed to prevent loosening and provide added security in various applications.

One of the key features of serrated safety locking washers is their serrated edges. These serrations create friction between the washer and the surface it is placed on, preventing rotation and loosening of the fastener. This makes them particularly useful in high-vibration environments or applications where there is a risk of unintentional loosening.

Serrated safety locking washers are commonly used in industries such as automotive, aerospace, construction, and machinery. They are often employed in critical applications where the integrity of the fastener is crucial. These washers can be used with a variety of fasteners, including bolts, screws, and nuts.

When selecting serrated safety locking washers, it’s important to consider factors such as material, size, and application requirements. These washers are typically made from materials like stainless steel or carbon steel, which offer durability and corrosion resistance. The size of the washer should match the fastener it will be used with to ensure proper fit and function.

Installing serrated safety locking washers is a straightforward process. Simply place the washer between the fastener and the surface, ensuring that the serrated side is facing the surface. Tighten the fastener as usual, and the serrations will grip the surface, providing a secure and reliable connection.

In conclusion, serrated safety locking washers are an effective solution for preventing loosening and enhancing the security of fasteners. Their serrated edges create friction, ensuring a tight and secure connection. Whether in automotive, aerospace, construction, or machinery applications, these washers provide added peace of mind.

| Size | M3, M4, M5, M6, M8, M10, M12, M16 |

|---|---|

| Pack Qty | 10 Units, 20 Units |

Brand

Universal-Hardware

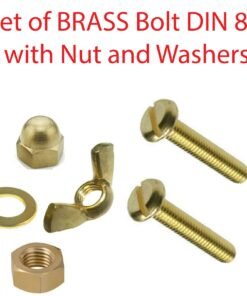

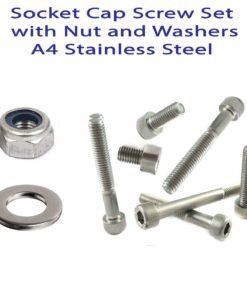

Related products

Fasteners

Hex head bolts set with Nylon Nuts and Washers Stainless Steel Fully Threaded Bolt (Pack of 5)