Lifting Eye Nut Made from Marine Grade A4 Stainless Steel 316

£2.95 – £39.00Price range: £2.95 through £39.00

Lifting Eye Nut Made from Marine Grade A4 Stainless Steel 316

Lifting Eye Nuts made from A4 Stainless Steel with the superior corrosion resistance make them a great choice for sailing, motor boating and other water-sports applications. Lifting eyes are commonly used as attachment points, cable attachments, rigging or rigging attachments or purely as lifting points these have a variety of uses.

A4 stainless steel lifting eye bolts provide maximum corrosion resistance for salt-water marine environments.

Strong lifting eye bolt with metric thread to create a secure fixing point, suitable for use in harsh marine environments. Orientate the eye bolt in line with the slings. If the load is applied sideways, the eye bolt may bend.

High quality Stainless Steel nuts also known as a Lifting eye nut made of durable A4 stainless steel. Full details and technical specifications below.

- What is A4 Stainless Steel? A4 grades of stainless steel are usually reserved for use in highly caustic environments where improved resistance to pitting corrosion is required, i.e Marine and exhausts. Pitting corrosion occurs once the chromium becomes exhausted through self-passivation after caustic attack – the effects as usually local to the exposed areas. The pitting forms as the Iron atoms become exposed to Oxygen and form ‘rust’.

How to use:

From time to time small parts and components need replacing on a wide range of machines and accessories for the automotive industry. We have the solution for many of these replacement problems. Used with a machine, spanner or cap screw for mechanically joining materials together. Used widely for matching screws or bolts.

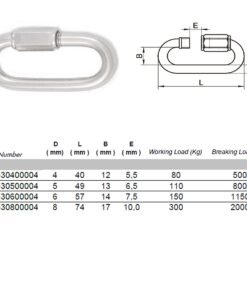

Technical Details

Lifting Eye Nut

M6

Outside diameter – 28mm

Thread size is M6

Inside diameter is 16mm

Overall height is 31mm

M8

Outside diameter – 36mm

Thread size is M8

Inside diameter is 20mm

Overall height is 36mm

M10

Outside diameter – 44mm

Thread size is M10

Inside diameter is 25mm

Overall height is 45mm

Color: Stainless Steel Finish

Counting Tolerances: We make every effort to count fasteners accurately using our professional counting weighing scales. As these scales are extremely sensitive, the slightest change in the working environment can have an effect on the instrument. Please rest assured that we expect over 99% of our orders to be correctly counted and packed, but we would like to advise you that a 5% tolerance either greater than or less than what you have ordered may be shipped. This will generally apply to the smaller ranges in our catalogue.

| Size | M6 / 6mm, M8 / 8mm, M10 / 10mm |

|---|---|

| Pack | 1 Unit, 4 Units, 10 Units |

Brand

Universal-Hardware

Related products

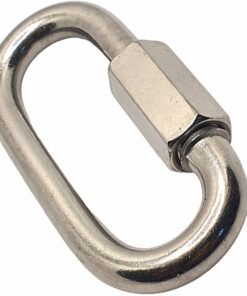

Marine Hardware

Marine Hardware

Marine Hardware

Marine Hardware